Sustainable Innovation

VanadiumCorp Electrochem Process Technology “VEPT”

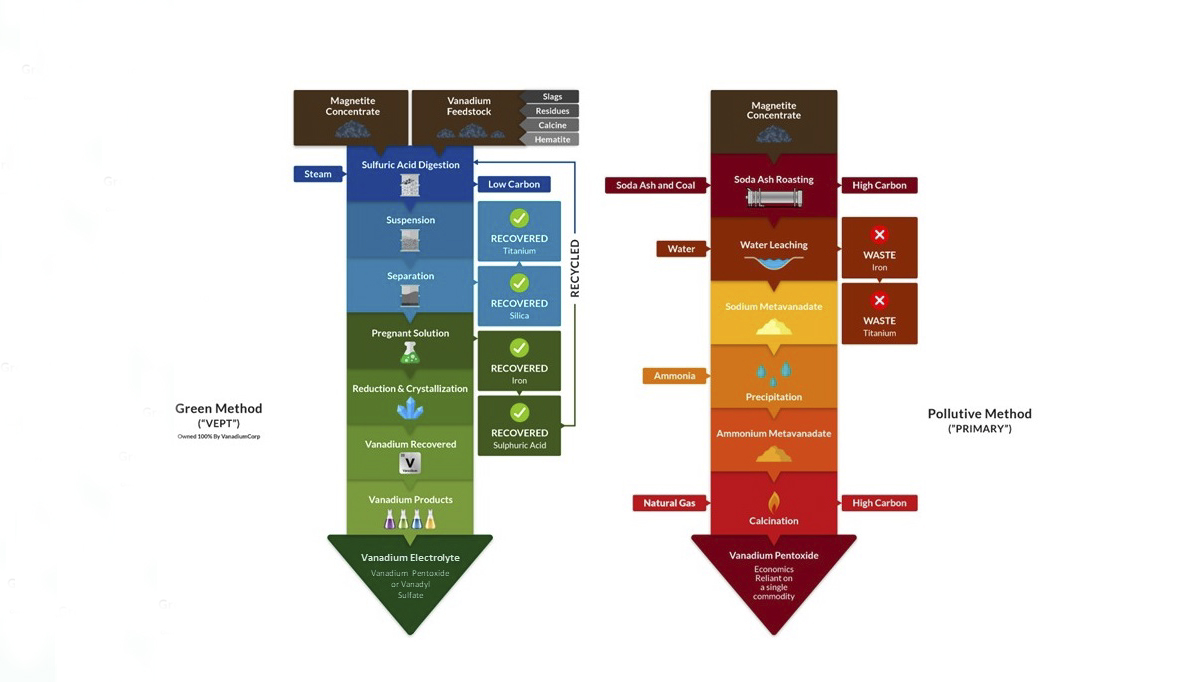

Conventional pyrometallurgical processes, for producing vanadium, utilize either direct soda-ash roasting of the magnetite, followed by water leaching, or the arc smelting and slagging of the magnetite followed by soda-ash roasting of the vanadium-rich slag. Smelting or roasting is capital intensive with high operating costs, technical risks, and significant emissions of greenhouse gases, that pose serious environmental issues. The VEPT addresses these key issues and allows the full recovery of vanadium to produce vanadium electrolyte (VE) or vanadium chemicals, as well as the concurrent production of titanium by-product, high quality, and competitive iron co-product and silica. The 100% owned VEPT is a novel chemical process, invented by Dr. Francois Cardarelli, that consists of digesting vanadiferous feedstocks into concentrated sulfuric acid. The technology addresses the recovery of vanadium pentoxide, vanadyl sulfate, ferrous sulfate, titanium hydrolysate, and silica from feedstocks such as vanadiferous titano-magnetite, iron ores and concentrates such as magnetite and hematite, vanadium industrial wastes such as BOF-slags, and other industrial by-products also containing vanadium.

Intellectual Property (IP)

IP Development & Ownership

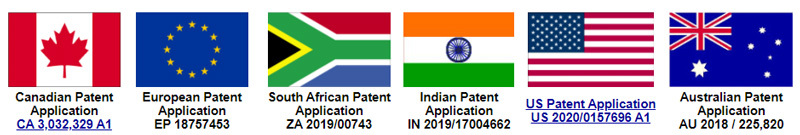

VanadiumCorp Resource Inc. has 100% ownership of US Provisional Patent Applications US 62/463,411 and US 62/582,060 and International Patent Application PCT CA2018/050196 entitled “METALLURGICAL AND CHEMICAL PROCESSES FOR RECOVERING VANADIUM AND IRON VALUES FROM VANADIFEROUS TITANOMAGNETITE AND VANADIFEROUS FEEDSTOCKS”

VanadiumCorp Resource Inc. has 100% ownership of US Provisional Patent Applications US 62/463,411 and US 62/582,060 and International Patent Application PCT CA2018/050196 entitled “METALLURGICAL AND CHEMICAL PROCESSES FOR RECOVERING VANADIUM AND IRON VALUES FROM VANADIFEROUS TITANOMAGNETITE AND VANADIFEROUS FEEDSTOCKS”

August 30th, 2018 – The World Intellectual Property Organization ”WIPO” (www.WIPO.int) officially published the Patent Cooperation Treaty “PCT” of the International Patent Application WO 2018/152628 (A1)

Download the International Patent Application “PCT” here

IP Portfolio – National Phases Complete

VanadiumCorp Resource Inc. owns 100% of the exclusive rights for the patented pending technology worldwide.

“Filing the National Phase Entry in Europe is the final and most significant milestone for VEPT essential to our developments in Europe that will integrate vanadium produced sustainably and directly into vanadium redox flow batteries to mitigate the cost and carbon footprint of energy storage.” Stated Adriaan Bakker, CEO, and President of VanadiumCorp.

“The National Entry Phase in Europe is a mandatory step towards commercialization of VanadiumCorp-Electrochem Processing Technology and compliments the recent validation and grant of our patented zero-carbon iron making process in the EU, successfully tested by our European customers, strengthens Electrochem’s unique intellectual property position for implementing future integrated plants in that key jurisdiction.” Stated Dr. Francois Cardarelli, President of Electrochem

Select jurisdictions where the patent protection for VEPT is filed and pending are:

Commercialization

Key Successes to Date:

- Construction of custom-built reactor pilot with 300 kg/month nameplate capacity

- National patent protection in key global jurisdictions and international

PCT published - Trial production of VanadiumCorp magnetite and vanadium feedstocks including waste residues from global companies

Core Objectives:

- Proceed with necessary engineering

- Integration into flagship vanadium project, Lac Dore

- Target commercial demonstration in existing infrastructure (TiO2 Plants)

- Produce eco-friendly and cost-effective vanadium electrolyte for VRFBs

Licensing or Partnership Mandate in Global Jurisdictions

On May 10, 2021, VanadiumCorp Resource Inc. commenced joint hydrometallurgical testing with Strategic Resources Inc. (TSXV: SR) (“Strategic”) using VanadiumCorp’s patented and proprietary green recovery process named the VanadiumCorp Electrochem Process Technology (“VEPT”) on titanomagnetite concentrate from Strategic’s wholly-owned Mustavaara Project in Finland. The ongoing prototype testing campaign is performed by Electrochem Technologies & Materials Inc. (“Electrochem”) at its facilities in Boucherville, Québec, Canada. It will test whether the clean energy technology from VanadiumCorp is viable on Mustavaara’s material and could provide an alternative and more environmentally friendly way to extract vanadium and iron, versus the conventional smelting methods evaluated in the Preliminary Economic Assessment for the Project (see Strategic’s news release dated May 4, 2021). Vanadium end products produced by the VEPT process favour the rapidly emerging Vanadium Redox Flow Battery industry in contrast to the current flowsheet, which produces ferrovanadium used in the steel industry. In addition, the process offers the potential for commercial-grade titanium production as a third revenue stream for the Project. Read the news release here…

Targeted Countries:

Core Objectives:

- Recover from high grade vanadium slag – No mine required

- Recover from metallurgy and demonstrate commercially

- Recover from vanadium resources with difficult metallurgy (Most in Australia)

- Upgrade with green option for mining projects with high waste and carbon footprint:

- Primary vanadium producers

- Secondary Vanadium Producers

- Steel Producers

- Titanium Producers