Vancouver, British Columbia – April 24, 2024 – VanadiumCorp Resource Inc.…

National Entry Phases Filed In Australia And Canada For Vanadiumcorp-Electrochem Processing Technology (VEPT)

![]()

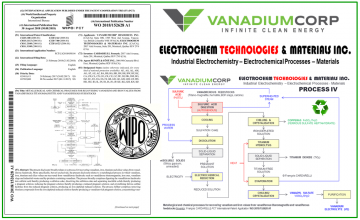

VANCOUVER, BRITISH COLUMBIA, February 14, 2019 – VanadiumCorp Resource Inc. (TSX-V: “VRB”) (the “Company”) and Electrochem Technologies & Materials Inc. (“Electrochem”) are pleased to announce the filing of the national entry phases in Canada and Australia of the international patent application: WO 2018/152,628 (A1) METALLURGICAL AND CHEMICAL PROCESS FOR RECOVERING VANADIUM AND IRON VALUES FROM VANADIFEROUS TITANOMAGNETITE AND VANADIFEROUS FEEDSTOCKS”. Subsequent filings made in other key jurisdictions will be announced as the patent office’s confirmations are received.

- National Phase Entry in Canada [CA 3032329]

- National Phase Entry in Australia [AU 2018225820]

The filing of the National Phase Entry in Australia will support Ultra Power Systems PTY Ltd goal of purchasing an Australian license of VanadiumCorp-Electrochem Processing Technology (“VEPT”) to expedite construction of the world’s first dedicated vanadium processing facility. (See VanadiumCorp News Release dated December 10, 2018). The filing of the National Phase Entry in Canada will support future plans for VanadiumCorp to address the North American market.

“The National Phase Entries represents a significant milestone for VEPT. VanadiumCorp and Electrochem are committed to near term commercial demonstration of VEPT. For vanadium specifically, VEPT addresses the largest industry challenges relating to price volatility and high carbon footprint in the current vanadium market. With VEPT, vanadium is recovered from vanadium-bearing feedstock efficiently with a lower carbon footprint. The patent applications filed in Canada and Australia will secure the vanadium supply, as these two jurisdictions are critical for future vanadium-titanium-iron production from vanadiferous titanomagnetite (“VTM”).” said Adriaan Bakker, CEO and President of VanadiumCorp.

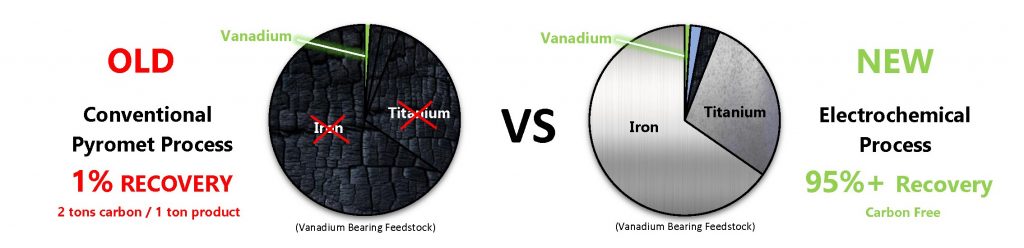

The jointly owned VEPT describes a novel chemical process invented by Dr. Francois Cardarelli that addresses the recovery of vanadium, iron, titanium, and silica feedstocks such as vanadiferous titano-magnetite, iron ores and concentrates such as magnetite and hematite, vanadium-containing wastes such as BOF-slags, and other industrial by-products also containing vanadium.

The process consists of digesting the vanadiferous feedstocks into concentrated sulfuric acid. The exothermic sulfation reaction allows the process to operate quasi-autogenously while producing a sulfation cake and hence minimizing the energy consumption drastically compared to smelting processing methods used by iron and steel producers. The dissolution of the sulfation cake with a minimum amount of water yields a dense pregnant solution and reduces significantly the water usage compared to the conventional roasting process utilized by existing primary vanadium producers. After reducing electrochemically, the pregnant solution is subjected to chilling and crystallization yielding pure crystals of ferrous sulfate heptahydrate (also named copperas). The process further recovers titanium hydrolysate by hydrolysis from the iron-depleted solution thereby producing a vanadium-bearing pregnant solution. The further concentration by evaporation and then a sequence of chilling and crystallization yields vanadyl sulfate as key precursor for the preparation of vanadium electrolyte (VE) used in vanadium redox flow batteries (VRFB) or for preparing various vanadium chemicals.

For convenient access to the PCT publication for VEPT, both Vanadiumcorp and Electrochem have allowed for direct download from both company websites using the following links:

VanadiumCorp: https://goo.gl/N8pPfU

Electrochem: https://goo.gl/i5QzqF

VanadiumCorp Resource Inc. In December 2018, VanadiumCorp and Electrochem signed a patent option agreement (POA) with Ultra Power Systems Pty Ltd. to purchase an exclusive license and construct a process plant for VEPT in Western Australia. Jointly developed and owned with Electrochem, this innovative chemical process allows for integrated and low carbon footprint recovery of vanadium, ferrous sulfate, and titanium hydrolysate needed on a global scale. VanadiumCorp also holds a significant vanadium-titanium-iron bearing resource base in mining-friendly Quebec, Canada including the 100% owned Lac Dore Project adjacent to Blackrock Metals Inc. and the Iron-T Project 3 km from the Glencore Matagami (Zinc-Copper) Mine.

Electrochem Technologies & Materials Inc. is a private Canadian corporation that invents, develops, patents, scales-up, and commercializes proprietary chemical, metallurgical and electrochemical technologies that are innovative, and sustainable. Electrochem currently owns twenty-four patents worldwide. The company also manufactures industrial electrodes, recycles rare earths, and produces tantalum and tungsten fine chemicals at its production facilities in Boucherville.

Vanadiumcorp Resources Ltd will be exhibiting at the annual PDAC Convention in Toronto (Booth Number: 2842), the world’s premier international event for the minerals and mining industry. It has attracted more than 25,000 people from 135 countries in recent years on March 3-6, 2019 at the Metro Toronto Convention Centre South Building, 22 Bremner Blvd, Toronto, Ontario M5V 3L9.

Vanadiumcorp wishes to clarify that in its news release of February 7, 2019, both vanadium projects were noted as adjacent to the Blackrock Metals project. It is the Lac Dore Project that is adjacent to the Blackrock Metals Project and the Iron-T Project is adjacent to the town of Matagami, near to the Glencore Matagami Mine, approximately 350 km west of the Company’s Lac Dore Project.

On behalf of the board of VanadiumCorp:

Adriaan Bakker, President and Chief Executive Officer

For more information, contact VanadiumCorp:

John Hewlett, Director, Business Development

By phone: 604-560-8251

By email: moc.procmuidanav@ofni

Website: www.vanadiumcorp.com

Neither the TSX Venture Exchange nor its Regulation Services Provider (as that term is defined in the policies of the TSX Venture Exchange) accepts responsibility for the adequacy or accuracy of this release